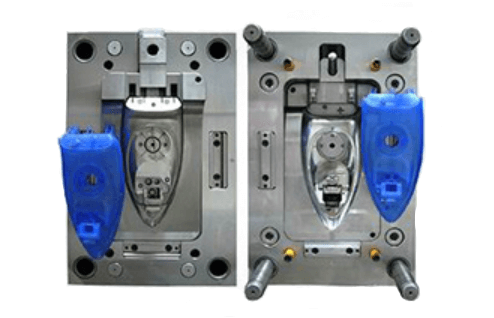

Tool Design / Mold Making Services Available

Mold Design & Fabrication

PCB Solutions produces precision injection molding with a steel insert of 0.005mm tolerance control. Another service we provide is large molds mounted on 1600-ton injection machines. Also, Our engineers are there every step of the way using programs such as ProE, Unigraphics, and mold flow analysis software. Above all, each of these programs will increase the overall effectiveness of price, capacity, and quality. Our EDM centers, EROWA quick clamping systems, and fine 0.1mm to 0.25mm diameter wire for wire-cut, along with newly installed high cavity hot runner system mold and stack mold (for medical, optical, electronics, and automotive cluster) in factories in China, Malaysia, and Singapore combine to fabricate over 250 molds a month with competitive lead times.

- Single cavity to multi cavities molds

- Standard and hot runner system molds

- Over mold and 2 components molds

- Precision and gear molds

- Insert mold and elaster molds

- Mold size for 10mt to 1600mt press

Precision Injection Molding Services

Because we use machines that range from 10-1600 tons, we can match any capability requirement. Furthermore, they do 1000mm/s which allows these molds to be finished when needed. The technology we use improves year after year because we always want your products to be of the highest quality.

We have the following capabilities:

Metal Injection Molding (MIM) Process

Another process is Metal Injection Molding (MIM) which mixes binder material with finely-powdered metal to produce a feedstock that is later used to make different molds. Most noteworthy is the fact that MIM allows high volume, complex parts to be molded even quicker. Finally, the molding undergoes conditioning operation to densify the powders and remove the binder.

Process 1 to 3: Feedstock Preparation

First of all, metal powders and polymer are mixed and then processed in a plastified binder at high heat. As a result we have what is called feedstock.

Process 4: Injection Molding Process

Next, we melt the binding additives so that the metal powder can flow. Later we remove the green parts from the mold once it cools down. Similarly, this is the same process used for plastic parts.

Process 5: Debinding Process

While keeping the shape of the components, the debinding process helps us obtain the desired parts. We do this thermally or chemically just depending on what material we are processing.

Process 6: Sintering Process

Finally, The sintering process can be thought of as the last touch because now we are eliminating the last of the unwanted parts on the inside. Consequently, there is a fair amount of shrinkage to the MIM parts with the sintering process which is why sometimes it is necessary to use heat and surface treatments to maintain the same form.

Secondary Processes

Surface and finishing treatment:

Silkscreen printing

Pad printing or transfer printing (Single to 4 colors)

Spray painting – Robots arm, Auto spindle

EMI shielding

UV Hard coating

Laser Etching

Mechanical and Electrical Assembly

Our assembly services include:

- Ultrasonic Welding

- Ultrasonic Insertion

- Heat staking

- Laser welding

- Soldering / Gasket Sealing

- Clean Room Assembly

- Module assembly

- Battery pack assembly

- Mobile speaker, Motor, Vibrator assembly

- Product Labeling

- ESD room assembly

- System Testing