How Does the Wiring Harness Help in Your Project?

Protecting the Project from Direct Damage

The wiring harness does more than merely keep the wires and cables tidy upon examination. While this is an important aspect for promoting a professional look to your finished product, the harness itself can serve multiple purposes for protecting electronics. This protection can come in the form of:

Preventing compromised wires from interacting within the product

Avoiding direct damage to those wires within the harness

Preventing damage from heat caused by various components

Protection Against Compromised Wires

A wire is still capable of transmitting data and/or electricity although it may have a small cut or otherwise exposed copper line. In many situations, these cuts could be incredibly small and difficult to identify. Often times these small cuts are caused by various tools and chassis installations. It’s not uncommon for electronics to remain completely functional as technicians may miss the compromised wire. By installing a harness over these wires, you reduce the chances of that particular wire from grounding out onto other components within the project. Components assembled onto the printed circuit board are incredibly sensitive and the slightest amount of charge can destroy the functionality of the PCB.

Preventing Direct Physical Damage

Wires contained inside a harness have an added layer of protection from various elements within any given project. Direct damage can be caused by a variety of objects ranging from screw drivers held by technicians to moving fans and other metallic parts within the chassis. Instead of compromising the plastic coating of a wire, the harness can absorb most, if not all, of the damage. This can help reduce the cause of product failure being attributed to damage to those particular wires and cables.

Preventing Damage from Heat

Electronic devices can create an incredible amount of heat. While this is usually dependent on the amount of power that is consumed by any particular device, the high temperatures can cause damage to wiring. Heated metal caused by the overall functionality of the device could melt through the protective plastic coating. Without a harness to reduce the damage, the wire could ground out on the metal object causing malfunctions and failure within the device.

Improving the Flow of Air Within the Chassis

A harness can do more than provide protection for the wires within. It can also improve the airflow within your project in order to optimize heat dissipation. As heat is one of the most damaging elements to any electronic device, being able to properly and efficiently cool the unit can prolong its usefulness. It is this threat that drives developers to create methods in which the device can maintain a cool temperature. This allows the heat to escape rather than cook the components attached to the PCB.

Larger units that produce more heat may be equipped with fans in order to dissipate hot air. Desktop units can create temperatures hot enough to cook meat. Without case fans to move the air out of the tower, the computer system could suffer a lot of damage in a very short amount of time.

Why the Wiring Harness is Important to Heat Dissipation

When it comes to ridding a device of hot air, a certain level of air flow is needed. Even if the object doesn’t have an exhaust fan, having an unrestricted path for hot air to follow and escape helps prevent the device from overheating. Inside electronic devices, wiring can cause an obstruction that prevents the air from escaping efficiently. This means that vent installations may not be as effective if there are wires blocking the flow of air.

Airflow

The harness contains various wires and reduces the impact these have on the flow of air within the unit. Instead of many wires stretched across this internal “jet-stream” of sorts, the harness can contain all of them within a single cable-like collection that can be easily and safely moved out of the way. This optimizes the space created in order to reduce the heat within any given object.

Dust

Dust within electronics can quickly reduce the lifespan of the unit. The airborne particulates that create dust collect onto sensitive electronic components. This collection acts like an insulation that prevents the heat from dissipating. Over time, the heat can build up and cause damage to the particular electronic component or even be responsible for overall PCB failure. With proper airflow due to wires being contained within a harness, it takes dust longer to collect onto these components.

Preventing Personal Injury

Harnesses can do a lot of good for preventing damage to the project or electronic device, but it can also prevent personal injury to technicians and developers. Although it is always a good practice to eliminate power completely from a project while working on it, there could be extenuating circumstances that would require the power to be live or perhaps a charged capacitor is within the object. With either case, the wiring harness can keep people safe from electrical shock. In projects that utilize a large amount of amps, additional protection could mean the difference between life and death. What ways can the harness protect technicians and other individuals involved with the development of the project?

Electrical shock through tools

Reduction of static discharge

Cleaner working environment

Electrical Shock

It doesn’t take a lot of amps in order to stop a person’s heart. While this is an extreme case when dealing with various projects, the damage can still be painful and damaging if not properly addressed. A capacitor used to create a flash of light in older styles of cameras can deliver an electrical shock that can be quite painful. The wiring harness can help prevent such situations from becoming a reality. Exposed copper can be hard to spot if you’re not looking for it, and touching one of those power supplying wires could cause more damage to the body than you may realize.

Static Discharge

Even the smallest amount of static electricity can cause severe damage to a PCB. In fact, dust containing the slightest of charges can cause an electronic device to ultimately fail. By limiting your actual contact with internal components of the project, you reduce the risk of completing a circuit with your body. Moving cables about by touching the harness can help eliminate the off-chance that you’ll touch something that will not respond well to a static discharge. Of course it’s a good practice to wear a static dissipating bracelet or touching a metal table prior to working on a live project.

Cleaner Working Environment

Many projects can be difficult to work on if there is a menagerie of wires strewn about the chassis. This can make for a difficult and dangerous task if power is still live to the unit. Having the wires contained within a harness can make troubleshooting, repairs and upgrades easier to conduct reducing the risk to the technician as well as the electronic components. The easier it is to see within any given project the easier it is to perform live maintenance without injury to yourself or damage to the project.

Other Ways the Wiring Harness Can Be Helpful

Protecting the internal environment of an electronic device or machine is the primary use of the wiring harness. However, there are many other ways that it can be helpful when developing your projects. These methods can increase the overall efficiency of the device while improving the efficiency of technicians as well. These other methods could include:

Color coordination for specific wire groups

Isolating connections that utilize a small area of the PCB

Adding style to projects that have an open chassis

Keeping power distribution wires collected and maintained

Improving installation of Molex attachments

Providing a tool-less method for damaged cable replacements

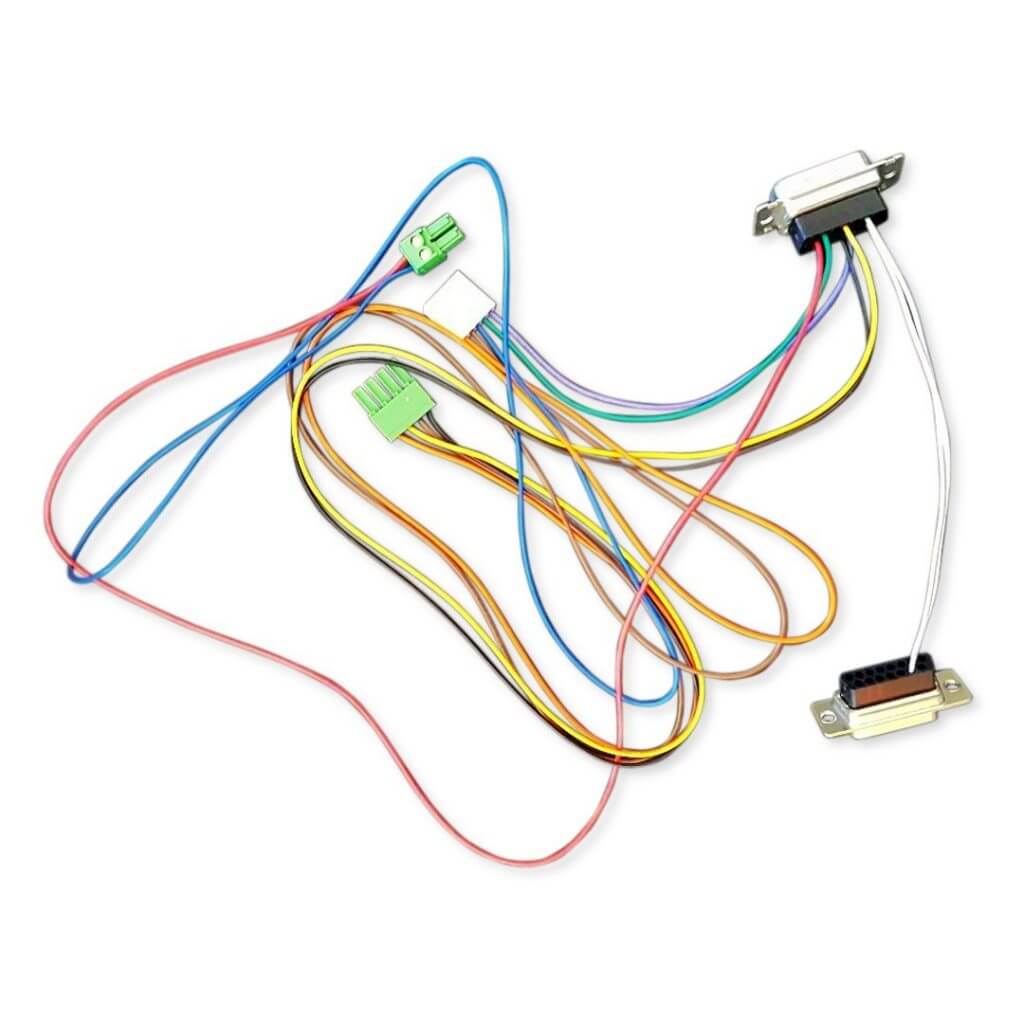

Color Coordination

As harnesses can be a variety of colors, you can assign specific project connections according to a key. For instance, power distribution harnesses could be signified by red while data transfer cables could be represented by blue. This could help you determine which wires are used by the system for specific needs. In a larger project where wiring could stretch quite a distance, you could find the correct collection with a mere glance at the harness.

Isolating Connections to PCB

In many projects, a collection of wires is needed for specific objects to function. This can be seen in connecting USB wires to a motherboard. USB can utilize up to seven individual wires for proper operation. Using a harness to isolate the wires can help developers find the correct ones to use for specific installations. Traditionally, USB connectors are combined within a single plastic cable. However, combining your project wires in such a manner could be as beneficial to you as the USB cable molding.

Adding Style

There are a variety of projects that utilize an open chassis. This is quite common in computer case modifications. A sheet of Plexiglas or acrylic displays the inner workings of a computer. Many technicians will implement reactive harnesses while utilizing UV cold cathodes to cause the harnesses to glow under the black light. This can create an impressive sight. Not all projects will utilize such grandeur, but it can provide ideas for future project developments.

Power Distribution Wires

Your project may be able to function without data interaction, but the power distribution may be an integral part of the project. Depending on how elaborate your design is, keeping various power distribution wires collected and isolated could make development of your project easier. This goes along with the sense of cleanliness mentioned earlier. It is much easier to work on a project without fighting against many wires each containing needed power for the unit.

Molex Attachment Installations

When installing new or upgraded Molex heads on cables, the task can be tricky if there are similar colored wires within the project. Unless you keep track of which wire came from which original Molex, you could inadvertently cause power supply damage through incorrect installations. By using a harness to contain a specific group of wires, you don’t have to worry about attaching the incorrect lines to a certain Molex. For instance, mixing the power wires between two different computer components could easily blow the power supply unit and/or the attached devices through variations in electrical wavelengths that do not match.

Tool-less Cabling for Projects

Perhaps you could design a tool-less method for cabling within your projects. Many computer power supplies are utilizing a similar design allowing power cables to be completely removed from the PSU itself. This greatly reduces the amount of wires within the computer’s chassis increasing airflow for heat dissipation. However, why stop there? You could design the entire project utilizing replacement cables in a similar fashion. Instead of wires being soldered to the printed circuit board, you could utilize connection modules on both ends for a tool-less repair and replacement of damaged wires.

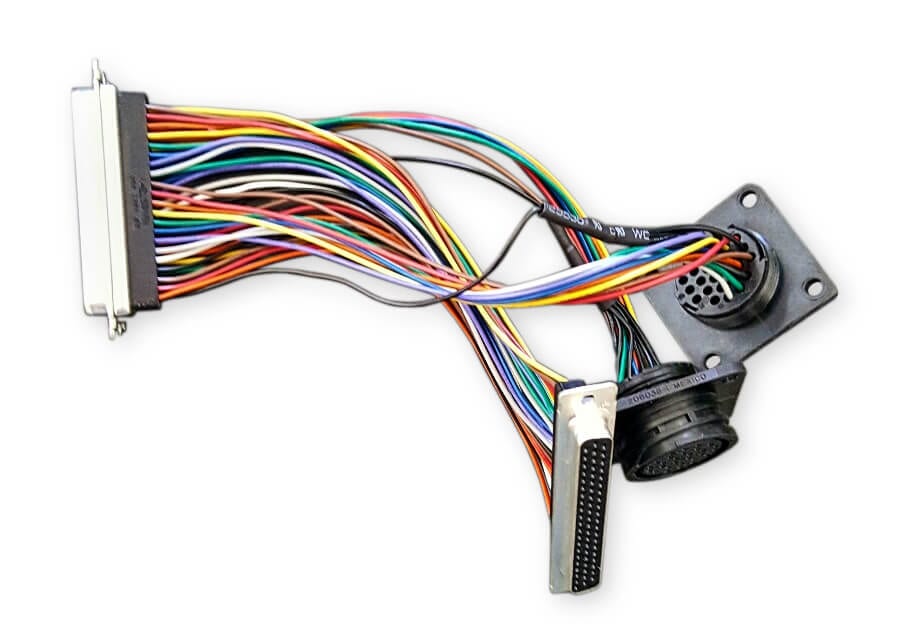

Dependable Wire Harness Products

Cable and wire harness products complement a variety of electronic manufacturing industries. As trusted wire harness manufacturers for hundreds of businesses across the world, we know just what it takes to create a high-quality custom cable assembly. Our services include designing, prototyping, splicing, strip and crimp as well as a number of other highly specialized cable harness manufacturing solutions. You can count on PCB Solutions to stay true to our promise of fast delivery times while maintaining highly-competitive prices – all of it without compromising on the quality our clients depend on.

Whether you need to improve heat dissipation or simply want to keep the chassis of your project tidy, wiring harnesses can do a great deal for your device. As a result, PCB Solutions creates the perfect wire harness for your project and improve its overall efficiency. Due to this, give your wired projects longevity and protection with custom designed and manufactured wiring harnesses.

Why Us?

PCB Solutions wire harnesses have the capabilities to make products best sellers. While some companies focus on price, and others focus on quality, we take pride in providing top rated products for any design while being competitive with others. Because we have such a high reputation in quality, we constantly renew and complete certifications so we stay up to date with the newest technologies.