PWB Surface Finish selection – Penny wise or pound foolish?

There is an old saying “Nothing solders like solder” but because of shrinking component footprints, environmental initiatives, cost, reworkability, mixed technology boards, ease of assembly and of course reliability finding the right finish for your product has made the selection of PWB surface finishes a little more complex.

There has been various attempts to solve the many issues, there was high hopes for the many finishes including Organic solderability preservatives, immersion silver, immersion tin, non leaded solder, electroless nickel immersion gold, flash gold, electroless nickel immersion paladium immersion gold however some are not available at all PWB shops, some designs require multiple surface finishes that are not compatible and all of them have their pros and cons.

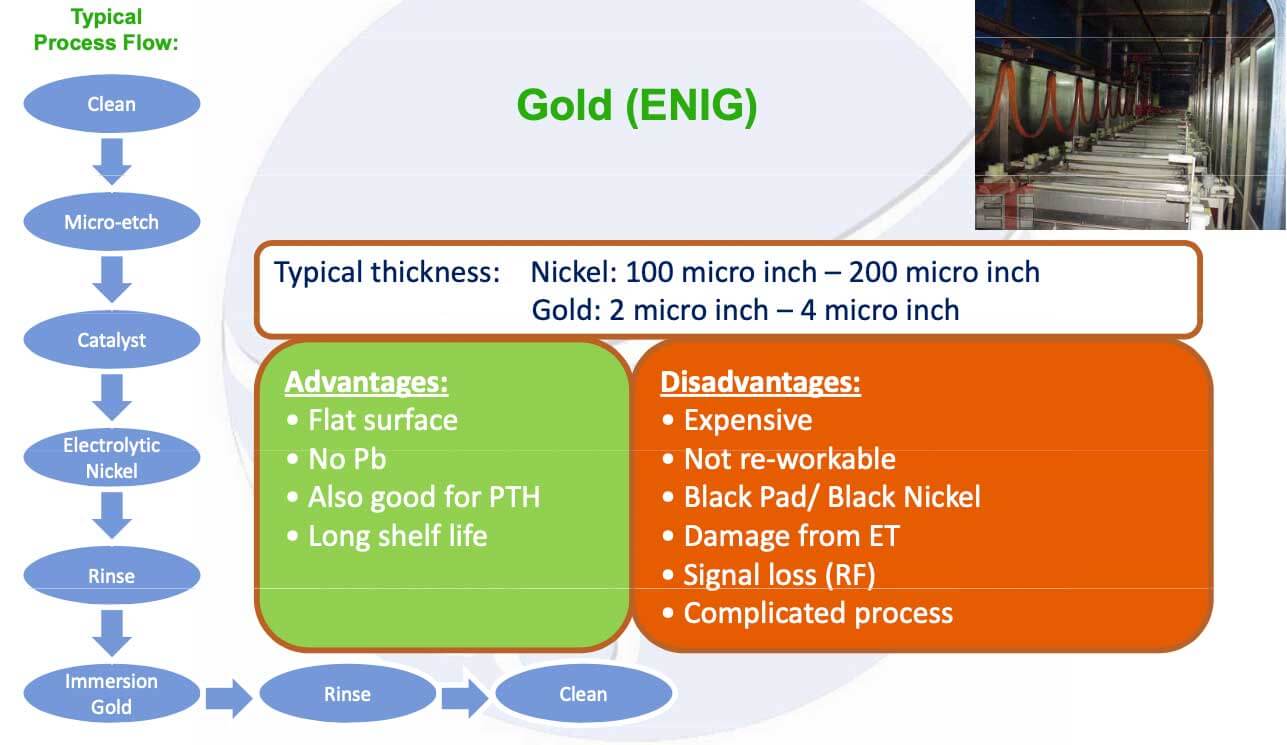

Other than the tried and true leaded solder, the one surface finish that seems to have lasted the longest and has gained the most acceptance is ENIG (Electroless nickel immersion gold) because it has a long shelf life, a flat surface and is still relatively inexpensive due to the gold’s ultra thin thickness even though gold prices are now reaching all time highs.

The selection of surface finish needs to done with your Electronic Manufacturing Service partner because when assembled boards have solderability issues, they are the ones that have to deal with the domino effect and headaches of costly rework and fleeting schedules.

If your surface finish is the cheapest but often requires assembly rework, the extra cost of a surface finish from the PWB shop is a fraction of the cost when schedules slip, rework starts and blame is in abundant supply.

Bob Neisius – Quality Manager, PCB Solutions

Surface Finishes Overview

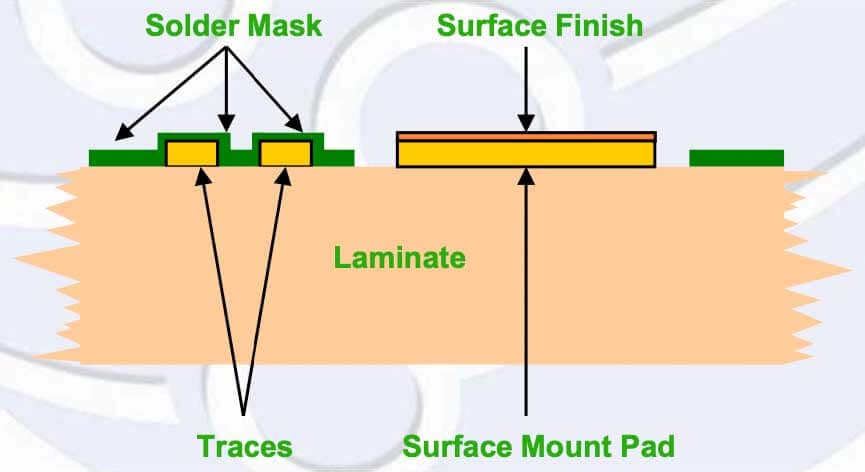

The PCB surface finish forms a critical interface between the component to

be assembled and the bare printed circuit board.

The surface finish has two essential functions:

- To protect the exposed copper circuitry.

- To provide a solderable surface when assembling (soldering)

the components to the board.

Most surface finishes are considered SMOBC (Solder Mask Over Bare Copper).

- Cost

- Reliability

- RoHS \ ELV \ WEEE

- Assembly method (Reflow, IR, Wave, etc…)

- Components used (BGA, QFP, DIP, SOIC, etc…)

- Durability

- Environment

- Shelf life

- Testability

- Productivity

- Failures (Black Pad, Tin Whiskers, etc…)

- HASL

- Lead Free HASL • Immersion Tin

- Immersion Silver • OSP / Entek

- Gold

- ENIG

- Full Body Flash Gold

- Hard Gold (Tabs)

- Hard Gold (Selective)

- Wire Bondable Gold

HASL / Lead Free HASL

Immersion Tin

Immersion Silver

Gold (ENIG)

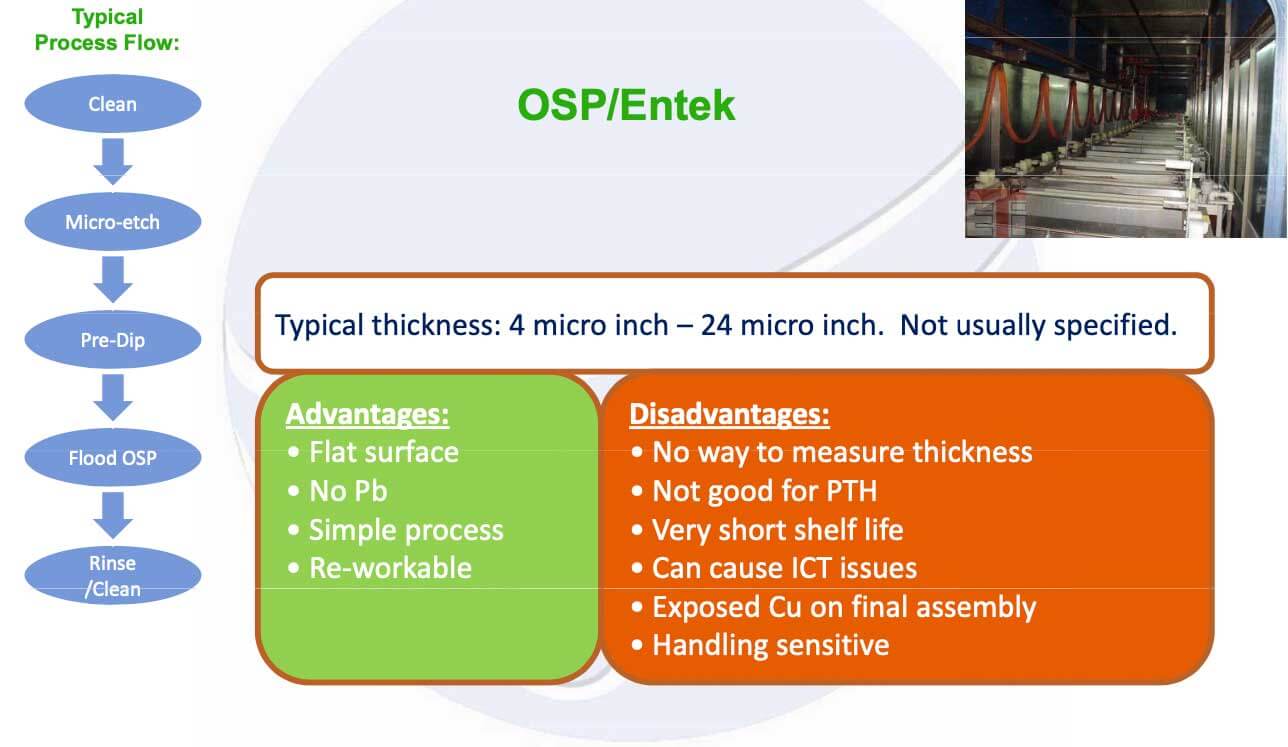

OSP/Entek

| Cost | RoHS˛ | |

| HASL | $ | No |

| Lead Free HASL | $ | Yes |

| Immersion Tin | $ | Yes |

| Immersion Silver | $$ | Yes |

| OSP/Entek | $$ | Yes |

| Immersion Gold | $$$ | Yes |

| Hard (Tab/Selective) Gold | $$$$ | Yes |